In quartz processing, mobile crushers have become the preferred equipment for mining enterprises due to their flexibility and high productivity. This article analyzes the parameters, customer cases, and market competitiveness of Liming Heavy Industry's 250+TPH quartz mobile crusher, helping you adopt efficient crushing solutions.

I. Core Product Advantages

1. Technical Highlights of Mobile Crushers

- Modular Design: Equipped with crawler/tire-driven systems for rapid relocation (30-minute setup) in complex terrains.

- Intelligent Control: PLC touchscreen monitors real-time power, pressure, and output size, with <0.5% failure rate.

- Eco-Friendly Performance: Sealed lubrication + dust removal system; noise ≤85dB; emissions meet national standards.

2. Quartz-Specific Configuration

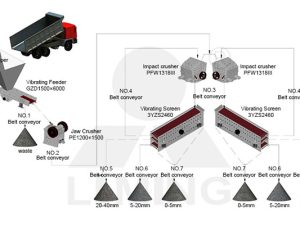

- Crushing Combo: Crawler jaw crusher (HXC96) + cone crusher (HXTSC250) + screener achieves 300TPH output.

- Precision Grading: Adjustable liners control output size (0.5-60mm) for construction aggregates and quartz sand.

II. Key Parameter Comparison

| Model | Capacity(t/h) | Feed Size(mm) | Power Configuration | Application Scenarios |

|---|---|---|---|---|

| LMH-250T Crawler | 250-300 | 1000×1200 | Diesel+Electric Dual Drive | Mountain mines, railway projects |

| LMH-250T Tire | 220-280 | 1100×1300 | Tri-Axis Hydraulic Drive | Urban construction waste |

| LMH-300T Hybrid | 280-350 | 1200×1400 | Dual Motor+Hydraulic Station | Large quartz processing plants |

Data source: Liming Heavy Industry Lab Reports

III. Client Case Studies

Case 1: Shandong Quartz Sand Plant

- Requirement: 500kt annual output; raw material 500-800mm → final product <0.5mm.

- Solution: LMH-250T crawler cone crusher + vibrating screen.

- Results: 40%↑ productivity, 25%↓ energy consumption, 99.2% purity.

Case 2: Hubei Construction Waste Project

- Setup: LMH-250T tire impact crusher + screening station processes 1,500t/day.

- Innovation: AI sorting removes metals/plastics; 95% recycling rate.

IV. Pricing & Service

1. Cost Breakdown (LiMing-250T)

- Base Configuration: Send a private message to get a quote (includes delivery/installation).

- Upgrades: Auto-lubrication + remote monitoring .

2. After-Sales Support

- 24/7 Response: 30 service centers nationwide; 48-hour on-site support.

- 3-Year Warranty: Free replacement of key components (e.g., mantle, liners).

V. Purchasing Guidelines

- Site Constraints: Crawler-type for rugged terrains; tire-type for urban transport.

- Material Hardness: Use manganese steel liners for quartz (Mohs 7 hardness; 30%↑ lifespan).

If you have any other questions, please contact our 24-hour online customer service