Granite (Mohs hardness 6-7) and basalt (Mohs hardness 5-6) are hard and highly wear-resistant, making them prone to causing equipment wear and reduced productivity during crushing. Choosing the right equipment is crucial for improving efficiency and controlling costs. Liming Heavy Industry offers a dedicated combination of high-efficiency crushers for hard rock crushing, covering the entire process of primary, secondary, and tertiary crushing, suitable for mainstream applications such as mining and aggregate production.

For primary crushing, Liming Heavy Industry's PE series jaw crusher is the preferred choice. Using the principle of compression crushing, the movable jaw and fixed jaw periodically compress the material. It is suitable for the initial crushing of large blocks of granite and basalt, with a maximum feed opening of 1200×1500mm, capable of handling large materials over 500mm. With a capacity of 30-1200 t/h, the wear-resistant liner is made of high-manganese steel, significantly reducing wear from hard rock and extending equipment lifespan, suitable for large-scale production needs.

JAW CRUSHER

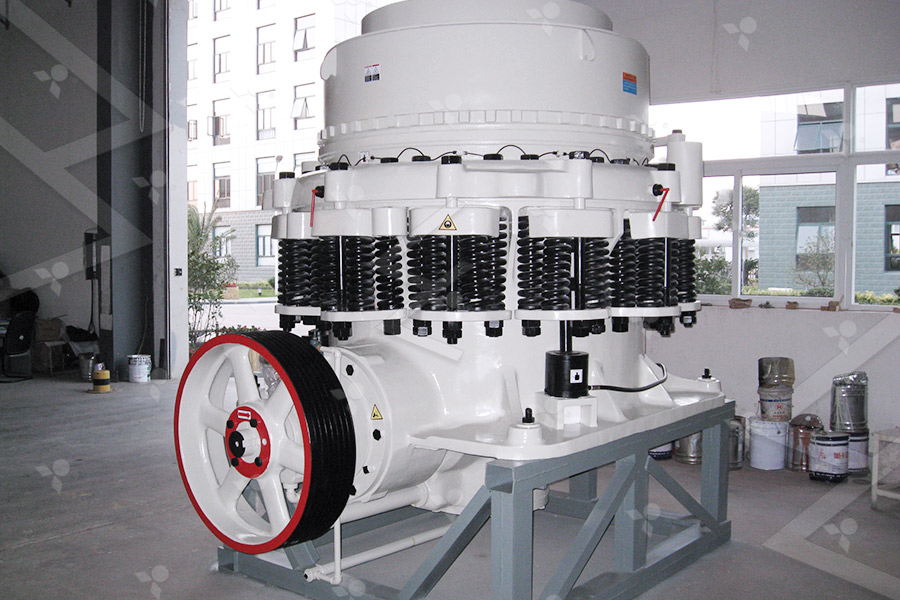

For secondary crushing, the CS series spring cone crusher is highly recommended. Designed specifically for hard rock, its optimized crushing chamber and inter-particle crushing technology improve crushing efficiency by 15% compared to traditional models. It can refine the material after primary crushing to 20-40mm, suitable for the secondary crushing of granite and basalt, offering both stability and economy, ideal for production lines with moderate output size requirements.

Spring Cone Crusher

For fine crushing and shaping, the HPT series hydraulic cone crusher is the optimal choice. Equipped with a Siemens PLC control system, it can precisely adjust the discharge particle size (3-60mm). The hydraulic protection system prevents metal impurities from damaging the equipment, handling unexpected situations during hard rock crushing. With a capacity of 45-1200 t/h, it is suitable for high-end aggregate production, producing uniformly shaped materials that meet the high standards of construction and road building.

HPT COEN CRUSHER

For mobile operations, Liming Heavy Industry's mobile crushing plant can be equipped with a jaw crusher or cone crusher as the main unit. It requires no fixed installation, offering flexible adaptation to multiple hard rock crushing sites and reducing material transportation costs. All models offer 24-hour after-sales service and maintenance, ensuring both efficient production and reliable support, making them a cost-effective choice for crushing granite and basalt.