1. Sandvik AutoMine® Core System

Sandvik's AutoMine® Core represents the pinnacle of automated crushing technology, combining advanced planning capabilities with underground autonomy. This comprehensive automation platform supports gradual transition from manual to fully automated production, featuring industry-leading solutions for underground connectivity, data analytics, and automated equipment options. Currently deployed in over 100 mines worldwide, including 20+ large-scale mining projects, AutoMine® Core delivers enhanced safety and productivity through seamless integration with digital ecosystems:ml-citation{ref="2" data="citationList"}.2. LIMING's 5G Remote Intelligent Control System

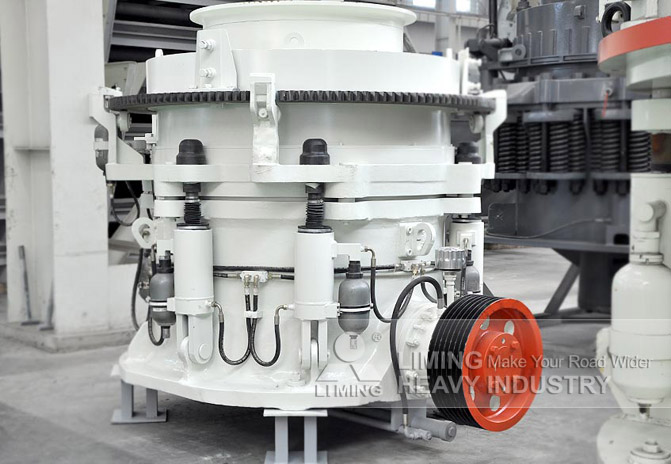

Liming Heavy Machinery Group's breakthrough technology features a 5G remote control system that enables operators to precisely control hydraulic crushers from thousands of miles away. With 140ms ultra-low latency and 360° panoramic vision through multi-camera and sensor fusion, this system achieves 45-second cycle times for "dig-load-dump-dig" operations. The fourth-generation technology incorporates naked-eye 3D holographic imaging for immersive operation, delivering 5% higher efficiency than traditional manual operations while extending daily working time by 1-2 hours.

3. Baker Hughes Integrated Mature Assets Solutions

Baker Hughes offers innovative hydraulic crushing solutions specifically designed for reviving mature mining assets. Their integrated approach focuses on value recovery and operational efficiency through advanced flare reduction technologies. These systems help mining operations extend equipment lifespan while maintaining high crushing performance, particularly valuable for operations looking to maximize existing infrastructure investments:ml-citation.4. Sandvik OptiMine® Digital Tool System

While primarily known for its automation features, Sandvik's OptiMine® system provides powerful analytical tools for optimizing hydraulic crusher performance in hard rock mining. This interoperable platform connects all assets (including non-Sandvik equipment) to deliver operational management tools and predictive insights. Its ability to integrate with various IoT devices provides real-time visibility into crushing operations, enabling data-driven decision making for efficiency improvements:ml-citation.5. TYHI's Intelligent "Health Butler" System

Complementing their remote control technology, Taiyuan Heavy Machinery's equipment health monitoring system sets new standards for hydraulic crusher maintenance. This intelligent "butler" continuously tracks equipment conditions, predicting maintenance needs before failures occur. Implemented across 40+ units in extreme environments from arctic to high-altitude mines, the system adds approximately $500,000 annual value per unit through reduced downtime and optimized performance.Performance Comparison

| Model | Key Feature | Efficiency Gain | Deployment Scale |

| AutoMine® Core | Comprehensive automation | 20-30% productivity increase | 100+ mines |

| LIMING 5G Control | Remote operation | 5% efficiency boost | 40+ units |

| Baker Hughes | Mature asset optimization | Extended equipment life | Various global sites |

| OptiMine® | Predictive analytics | 15-20% process improvement | Integrated with AutoMine® |

| TYHI Health System | Predictive maintenance | $500K/year value per unit | 40+ units |