When selecting crushing equipment for quarry projects, choosing between impact crushers and jaw crushers is a critical decision. Both machines serve distinct purposes in material processing, and understanding their differences can significantly impact your project's efficiency, cost, and output quality.

Key Differences Between Impact Crushers and Jaw Crushers

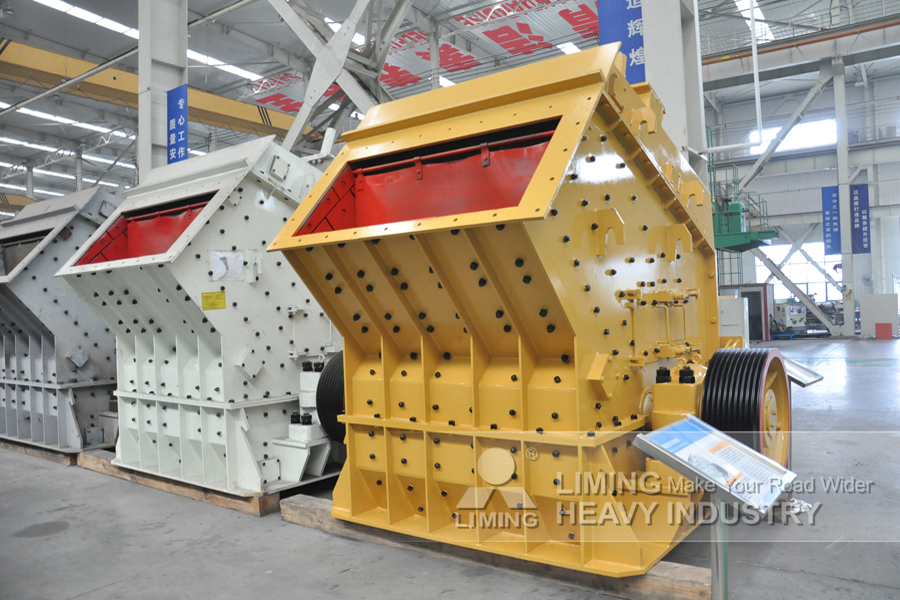

Impact crushers and jaw crushers operate on fundamentally different principles, leading to distinct performance characteristics. Jaw crushers utilize compressive force through fixed and moving jaws to crush material, making them ideal for primary crushing of hard, abrasive materials like granite and basalt. In contrast, impact crushers employ high-speed rotor impact to fracture materials, excelling at producing uniformly shaped aggregates from softer rocks such as limestone.

Performance Comparison: Data from Liming Heavy Industry

| Parameter | Jaw Crusher (PEV-1200×1500) | Impact Crusher (PF-1820) |

|---|---|---|

| Max Feed Size | 1020mm | 600mm |

| Output Capacity | 220-450 tph | 100-260 tph |

| Final Product Size | 10-300mm | 5-50mm (adjustable) |

| Power Consumption | 160-220 kW | 250-315 kW |

| Wear Part Cost | $0.08/ton | $0.12/ton |

Choosing the Right Crusher for Your Quarry

Selecting the appropriate crusher depends on your quarry's specific material characteristics and production goals. For hard, abrasive rocks requiring primary crushing with large throughput, jaw crushers typically offer superior efficiency and lower operating costs. Conversely, when processing softer materials or needing precisely shaped aggregates for construction purposes, impact crushers provide better end-product quality despite higher per-ton wear costs.

Consider factors such as feed material hardness, desired output size distribution, and production capacity requirements when making your decision. Many quarry operations achieve optimal results by combining both crusher types in a multi-stage crushing circuit.