1. A Brief Introduction To Water Conservancy Projects

Water conservancy projects refer to the rational development, utilization and protection of water resources through the construction of dams, channels, pumping stations, reservoirs and other facilities. Such projects are widely used in flood control, irrigation, power generation, water supply and other fields, and are one of the key points of national infrastructure construction. In the construction process of water conservancy projects, a large amount of stone materials often need to be processed, such as riverbed cleaning, dam filling, slope protection construction, etc., and mining crushers have become indispensable key equipment.

2. The Role Of Stone Crushers In Early Engineering Projects

In the early stages of water conservancy project construction, it is usually necessary to crush the original stones mined or excavated to meet the particle size requirements required by the project. The main functions of stone crushers include:

Raw material pretreatment: crushing large rocks into smaller particles suitable for transportation and subsequent processing.

Improve construction efficiency: reduce the labor intensity of manual crushing and speed up the progress of the project.

Optimize material properties: crushed stones can be used for concrete aggregates, roadbed filling, etc. to improve project quality.

3. Introduction Of Stone Crusher

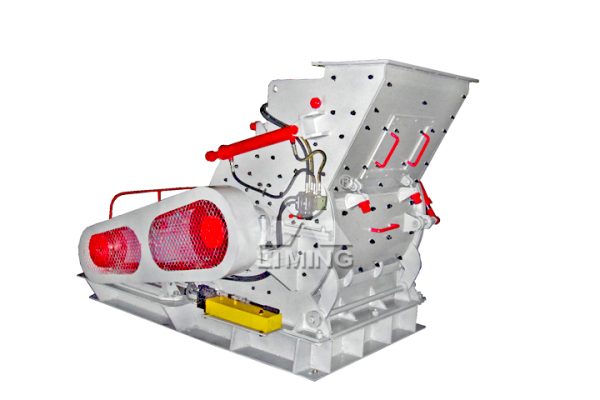

There are many types of mining crushers, including jaw crusher, impact crusher, cone crusher, hammer crusher, etc., which are suitable for crushing stones of different hardness and particle size.

Main Types And Features

Jaw Crusher: suitable for coarse crushing, processing large rocks, simple structure, easy maintenance, and production capacity of 100-1500 tons/hour.

Impact Crusher: suitable for medium and fine crushing, good finished product shape, suitable for concrete aggregate production in water conservancy projects, production capacity of 50-500 tons/hour.

Cone crusher: suitable for high-hardness rock crushing, strong wear resistance, stable operation, production capacity of 100-800 tons/hour.

Hammer Crusher: suitable for soft rock or medium-hardness stone, large crushing ratio, production capacity of 50-300 tons/hour.

Core Advantages

- High efficiency and energy saving: using advanced crushing technology to reduce energy consumption and improve production efficiency.

- Strong adaptability: It can process stones of different hardness and humidity to meet the diverse needs of water conservancy projects.

- High degree of automation: Some models are equipped with intelligent control systems to reduce manual intervention and improve safety.

4. Points To Note When Purchasing Crushers In Water Conservancy Projects

When purchasing crushers suitable for water conservancy projects, the following factors need to be considered comprehensively:

(1) Project demand analysis

Stone hardness: Cone crushers are recommended for high-hardness rocks such as granite and basalt, and impact or hammer crushers can be selected for medium- and low-hardness rocks such as limestone.

Capacity requirements: Select the appropriate processing capacity according to the construction scale to avoid equipment overload or capacity waste.

(2) Equipment performance evaluation

Wear resistance: Water conservancy projects usually require long-term continuous operation, and crushers made of wear-resistant materials should be selected, such as high-manganese steel jaw plates, alloy hammer heads, etc.

Environmental protection: Give priority to low-noise equipment equipped with dust removal devices to reduce the impact on the environment.

(3) After-sales service and cost

Manufacturer reputation: Choose a well-known brand to ensure equipment quality and after-sales support.

Maintenance cost: Investigate the replacement cycle and price of wearing parts to reduce long-term operating costs.

(4) Site adaptability

Installation space: The space on the water conservancy project site may be limited, so you need to choose a model with a compact structure that is easy to transport and install.

Mobility requirements: If the construction site is changeable, you can consider a mobile crushing station to improve flexibility.

Mining crushers play a vital role in water conservancy projects. Choosing the right equipment can not only improve construction efficiency, but also reduce project costs. When purchasing, be sure to combine the actual needs of the project and comprehensively consider the equipment performance, production capacity, wear resistance and after-sales service to ensure the smooth progress of the project. If you need further consultation on crusher selection, please contact professional suppliers for customized solutions!