What is construction waste? Construction waste refers to the construction waste materials produced in the project due to man-made or natural reasons, including waste slag soil, abandoned soil, silt and discarded materials. These materials are not helpful for the construction itself, but are substances produced in the process of construction, and need to be processed accordingly so as to achieve the ideal construction of the project, precisely because it is a whole process, so the consideration of its link is more important.

Concrete rubble debris on construction site

Construction Waste Sorting Process Analysis

1. construction waste sorting

Construction waste into the processing area, by the loader will be sent to the garbage artificial roughing system, there are manually operated garbage roughing system on the garbage roughing, bagged garbage implementation of the broken bag, the garbage in the soft fibrous material (such as rags, woven bags, broken lint, etc.), wood blocks, length longer than 300mm of waste steel and other non-breakable material implementation of the separation, focusing on the separation of pure coagulated chunks.

2.small pieces of material feeding

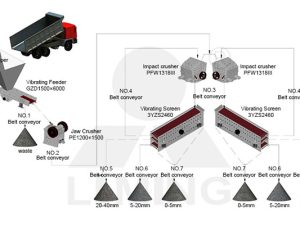

After rough selection of small pieces of garbage by the loader into the vibrating feeder to implement the mud and uniform feeding, soil, dust and other debris by the conveyor belt centralized output. The construction aggregate is fed into the jaw crusher.

3. Large material crushing

Large pieces of garbage are crushed by the crusher and sent to the vibrating feeder after crushing, in which the construction aggregate is input into the jaw crusher.

The construction aggregate enters the jaw crusher for crushing, and the material discharged from the discharge port enters the manual sorting conveyor belt, and the debris in the garbage is sorted out by manual labor.

5. Magnetic Separation and Impact Crushing

Above the sorting belt, a self-discharging belt iron remover is designed and equipped to effectively separate the magnetic substances in the garbage from the garbage. The manually sorted garbage is sent to the impact crusher through the conveyor belt for fine crushing of useful aggregates.

6. Four-deck vibrating screen

The finely crushed material is sent to the large tumbler screening machine through the conveyor, and the screening machine will screen the material. Configuration of 5mm, 10mm, 20mm and 30mm four screens, respectively, the material will be screened into particle size 0-5mm, 5-10mm, 10-20mm, 20-30mm materials, materials larger than 30mm through the conveyor back to the impact crusher for re-fine crushing. This screening machine can be used to treat construction waste in special cases to realize the reduction.

7: Inorganic material utilization

0-5mm fine aggregate can be used as building backfill or for road base, 5-10mm fine aggregate is used for production of building blocks, such as solid standard bricks, porous bricks, bricks for municipal use, hollow blocks and shaped bricks, etc. 10-20mm coarse aggregate and 20-30mm coarse aggregate are used for the production of commercial concrete or PC cement precast components.

Construction waste sorting crusher is an environmentally friendly, effective and intelligent construction waste treatment equipment with wide application prospects and market demand. With the deepening of the concept of environmental protection and the rapid development of the construction and renovation industry, the market demand for construction waste sorting and crushing machine will be more and more large, with good investment value and development prospects.